The Article

The name of the article is “Molten salt reactors were trouble in the 1960s—and they remain trouble today.”, authored by M. V. Ramana and appearing 20 June 2022 on the website of the Bulletin of Atomic Scientists. Keep in mind that the Bulletin of Atomic Scientists are the keepers of the “Doomsday Clock” – a relic of the cold war era designed to keep Joe Public scared and the public funding coffers open so the industrial-military complex of the west could continue building nuclear weapons. The links is the end of this article.

The Doomsday Clock has been ticking for 70 years. It’s time to let it die.

Why I’m giving up on the apocalypse countdown., Shannon Osaka, Reporter

We could spend hours rebutting and refuting every single piece of purported evidence submitted by the article, but that is not smart thing to do. And it’s not actually the point. When you understand the meaning behind the article a direct refute is actually a waste of time.

Not a Technical Data Review nor a Rebuttal of Technical Content

But, on the technical competence of Thorium Molten Salt technology, we have spent many hours interviewing the last surviving members of the research programs of the 1960’s and 1970’s. We can state that all the claims in the article we have reviewed are bogus. Hence our review here.

The article was clearly a hit piece from the start, so it must be assessed as one. We will review the writing style and the techniques used to make it appear a useful and credible piece. But in fact it is not at all. It has nothing to do with science and everything to do with objectives that are not clear from the article itself.

The article creates a dismal portrayal of actual events, and doubt and hesitation in the mind of the uninformed reader. Even a nuclear scientist who hasn’t studied the MSRE could nod their head in agreement – unless they critically review how the data is presented.

If used skillfully, the article would be a damaging success and Thorium Molten Salt would remain on the shelf.

The article is designed to be given to a senator or congress member (India, USA, German etc.) who might be teetering on the edge of supporting the best form of energy generation we have: Thorium Molten Salt.

This article could also be used to commit USD billions of public money to dilute and bury U233. Who owns the contracting companies work in the place where they will bury it? Follow the money.

It’s unfortunate that such people exist who put their name to such work, but hey, it’s not a game without an opponent.

Lessons First: How to Distract with Writing

Firstly here’s some pointers on how to attack something with an article, without making it appear like an attack. There are certain techniques that a writer can use to make their writing appear full of valuable data while dissuading further analysis.

These techniques include:

- Overloading the article with technical jargon and complex language that is difficult for laypeople to understand. This can make the reader feel overwhelmed or intimidated, and discourage them from delving deeper into the topic.

- Presenting only one side of the argument, and ignoring or downplaying any opposing viewpoints or evidence. This can create the impression that the author has provided a complete and conclusive analysis, when in reality there may be much more to consider.

- Using emotionally charged language or rhetoric to appeal to the reader’s emotions, rather than presenting objective facts and evidence. This can make it difficult for the reader to separate the author’s opinion from the facts of the matter.

- Limiting the scope of the article to a narrow or specific aspect of the topic, without providing a broader context or perspective. This can make it seem as though the topic is fully explored, when in reality there may be many other important factors to consider.

Other variations of techniques that can be used to appear scientific and fact-based while actually presenting a biased or negative view of the subject matter. can be:

- Selectively citing studies or data that support the writer’s viewpoint while ignoring or downplaying studies or data that contradict it.

- Using loaded language or emotional appeals to discredit the subject matter or those associated with it.

- Employing a one-sided or cherry-picked narrative that presents a biased view of events or situations.

- Using innuendo or insinuation to suggest negative associations with the subject matter, without providing clear evidence to support the claims.

The Authors Background

Let’s now consider the author. Who is he and what is his beef with Thorium? It’s important to understand their position and who or what they may be supporting in the background.

On face value, it seems that M. V. Ramana is a well-respected expert in nuclear disarmament. He has published extensively on the subject, and his work has been recognized with several awards and appointments to prestigious organizations. Ramana’s focus on disarmament and nuclear risk assessment suggests that he is concerned about the potential dangers of nuclear power and views it as a threat to global security.

Given his expertise in the field and his focus on disarmament, it is not surprising that Ramana is critical of Molten Salt Burners. His emphasis on the risks associated with this technology, such as accidents and proliferation concerns, have been debunked in numerous papers and reports, however it obvious that Ramana still views them as unacceptable given the article and his general concerns about the nuclear topic. Additionally, his affiliation with groups such as the International Nuclear Risk Assessment Group and the team that produces the World Nuclear Industry Status Report suggest that he is part of a broader movement to promote other energy options, which may lead him to be sceptical of any nuclear technologies.

However, upon reviewing the previous articles Ramana has authored or co-authored, notably absent is anything about UK’s plans to increase their nuclear arsenal. The UK needs to boost their uranium fired power industry to give cover for plutonium production. The material is necessary for the additional 80 Trident warheads the UK intends to build in the next few years.

You can dive down that rabbit hole of more nuclear weapons with these links:

UK Planning for Rapid Nuclear Expansion

UK Increases Nuclear Arsenal Article 1 – Reuters

UK Increases Nuclear Arsenal Article 2 – Guardian

Having no article on this is strange considering Ramana’s position as chair of a non-proliferation organization, and his propensity to produce articles. There are 33 articles on The Bulletin alone with his name attached.

However one must consider what the UK has been doing to rubbish Thorium. We will touch on it here but it does deserve a full article in the near future.

Put frankly, after the IAEA published their technical memo 1450 in May 2005 supporting Thorium as a fuel and identifying it’s non-proliferation features, the UK set about the systematic vilification of Thorium. An anti-Thorium article by three learned (but non-nuclear) Cambridge professors; a publicly funded 1.5 million GBP “no-to-Thorium” research report by a single person consultancy that referenced Wikipedia as a source; the gagging of a Lord; the possible early demise of the former head of Greenpeace UK, who had switched to Thorium. Then, the announcements of new nuclear energy for UK and shortly thereafter new nuclear weapons. It’s the makings of a sinister plot of a Bond movie. Or perhaps more akin to a “Get Smart” episode, or indeed, for the UK, “Yes, Minister”.

IAEA Technical Memo 1450 Thorium Fuel Cycle Potential Benefits and Challenges

Be sure to consider this IAEA report on Thorium focuses on solid fuel uses. This is not ideal. This is addressed very well by Kirk Sorensen in 2009 and you can read that here:

A Response to IAEA-TECDOC-1450

So the question is, does Ramana receive funding or any kind not to discuss new weapons for the UK? Has he been prompted (paid) to weigh into the argument against Thorium because of these plans?

We will never know these answers.

Review of the Writing Style of the Article

Launching into the article itself, here are some of the techniques that have been used manipulate readers.

Emotional Language

Use of emotional language. The author uses words like “trouble” and “hype” to describe molten salt machines, which could instill a negative emotional response in readers and make them less likely to consider the technology objectively. The author refers to the “failed promises of nuclear power,” which may be intended to evoke a sense of disappointment or disillusionment with nuclear energy in general.

Cherry Picking Data

Cherry-picking data. The author points out that “no commercial-scale molten salt reactors have ever been built,” which could be interpreted as evidence that the technology is unproven or unreliable. However, this overlooks the fact that of the numerous activities worldwide to commercializes the technology. There are several countries and many private companies actively pursuing new molten salt reactor designs.

The author notes that molten salt reactors require “materials that can withstand intense radiation and high temperatures,” which could be interpreted as a major technical challenge. However, this overlooks the fact that many materials capable of withstanding extreme conditions already exist, and that ongoing research is aimed at developing even more robust materials.

Logical Fallacies

There’s multiple use of logical fallacies. Here are two examples:

Example 1: The author suggests that because molten salt reactors were initially developed as part of a military program, they are inherently problematic or dangerous. This is a classic example of an ad hominem fallacy, which attacks the character or motives of an argument rather than addressing the argument itself.

Example 2: The author implies that because molten salt reactors were not ultimately adopted for commercial use in the 1960s, they must be fundamentally flawed. This is an example of a false dilemma fallacy, which presents only two options (in this case, success or failure) and overlooks more nuanced or complex possibilities.

Appeal to Authority

Used extensively is appeal to authority. The author repeatedly references well-respected scientists and institutions to bolster his argument against molten salt reactors. While it’s important to consider expert opinions, the constant invocation of authority figures can also be a way to shut down debate and discourage readers from doing their own research. For example, he cites a report from the Union of Concerned Scientists that characterizes molten salt burners as “inherently dangerous,” but doesn’t provide any details about the methodology or findings of the report.

Fear-Mongering

Basic Fear-mongering is used. In addition to playing up the potential risks of molten salt burners, the author also seems to imply that proponents of the technology are somehow sinister or untrustworthy. For example, he writes that “The companies and individuals involved in promoting this technology today have made claims that range from the dubious to the outright false.” This kind of rhetoric can be effective at turning readers against a particular idea or group, but it doesn’t necessarily contribute to a reasoned discussion of the topic at hand.

Oversimplification and Generalization

There are examples of oversimplification. While the author does acknowledge that there are some potential benefits to molten salt burners, he ultimately argues that they are too risky and impractical to be a viable solution to our energy needs. However, his arguments often rely on oversimplifications or generalizations that don’t fully capture the nuances of the technology. For example, he writes that “One of the main reasons molten salt reactors were abandoned in the 1960s was their inherent safety problems,” without providing any additional context or elaboration on what those safety problems were. This kind of oversimplification can be misleading and obscure important details that might challenge the article’s argument.

Overall, it’s clear that the author is deeply skeptical of molten salt burners and believes that they are not a viable solution to our energy needs. While it’s important to consider potential risks and drawbacks associated with new technologies, it’s also important to have an open and nuanced discussion about their potential benefits and drawbacks. The techniques used in the author’s article are also manipulative and intellectually dishonest, and readers should be aware of these techniques as they consider his argument.

Further Reviews

Now here are three credible reviews by three very different professionals:

- A pro-nuclear scientific author with a PhD in nuclear physics.

- Another science author but with a PhD in psychology and no nuclear training whatsoever.

- An environmental scientist and environmental advocate looking for a solution (a degree in environmental science).

Pro-Nuclear Scientific Author

I am a pro-nuclear supporter, and must be since I am also a Doctor of Nuclear Physics, I reviewed the article “Molten salt reactors were trouble in the 1960s—and they remain trouble today” by M. V. Ramana. I will focus on the blatant non-scientific methods used to discredit a perfectly viable technology.

The article discusses the popularity of molten salt nuclear reactors among nuclear power enthusiasts, and their potential to lower emissions, be cheaper to run and consume nuclear waste, and be transportable in shipping containers. The article mentions how various governments and organizations have provided funding for the development of these reactors. However, the author asserts that this technology was unsuccessful in the past and is the solution to our current energy problems.

The author uses a several subterfuge techniques to support his argument. Firstly, he uses loaded language to portray molten salt reactors as a risky and problematic technology. For example, he uses the phrase “all the rage among some nuclear power enthusiasts” to imply that people are overly enthusiastic about this technology. The phrase “trouble” in the article’s title also suggests that molten salt reactors are problematic. Additionally, the author uses the phrase “legendary status” to describe the Molten Salt Reactor Experiment, which is a hyperbole that can exaggerate the reactor’s success and, therefore, make it seem like a risky venture.

The author uses a strawman argument to discredit molten salt reactors’ developers and proponents. By implying that these people believe that the Molten Salt Reactor Experiment was so successful that it only needs to be scaled up and deployed worldwide, the author sets up a weak and exaggerated version of the opposition’s argument, which is easy to refute.

The author uses an appeal to emotion by asking readers to adopt a 1950s mindset to understand the interest in molten salt machines. The author makes an emotional appeal by stating that breeder machines would allow humanity to live a “passably abundant life.” By doing so, the author tries to persuade readers that using molten salt machines would not lead to a more abundant life, which is an emotional argument rather than a logical one.

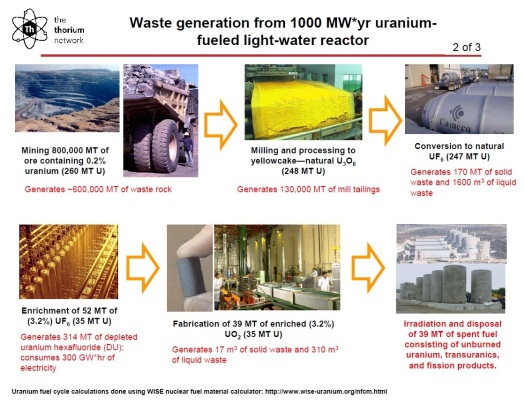

The author provides detailed information on the fuel used in the MSRE, including depleted uranium, highly enriched uranium (HEU), and uranium-233 derived from thorium. However, the author uses subterfuge by presenting the information on the fuel without providing any context on why these fuels were used. HEU was used during that time because it was the only fuel that could sustain the reactor at high temperatures. Uranium-233 was derived from thorium, which is more abundant than uranium, and the intention was to use this as a breeder fuel to produce more fissile material.

The author then goes on to criticize the MSRE by stating that the reactor failed to reach its intended power output of 10 MW. However, this information is presented without any context on the significance of this failure. The MSRE was an experimental reactor, and its primary goal was to test the feasibility of the technology. The fact that the reactor was operational for four years and achieved a maximum power output of 8 MW is significant in demonstrating that the technology was viable.

The author also highlights the interruptions that occurred during the operation of the MSRE, including technical problems such as chronic plugging of pipes, blower failures, and electrical failures. However, these issues are common in any experimental reactor, and the author fails to provide any context on the significance of these issues. It is essential to note that the MSRE was the first and only molten salt reactor to be built, and it was an experimental reactor. Therefore, the primary goal was to test the feasibility of the technology, and it was expected to encounter problems.

The author argues that materials must maintain their integrity in highly radioactive and corrosive environments at elevated temperatures. The corrosion is a result of the reactor’s nature, which involves the use of uranium mixed with the hot salts for which the reactor is named.

The article uses the technique of “cherry-picking” when discussing the material challenges in the manufacturing of molten-salt-reactor components. While the author acknowledges that Oak Ridge developed a new alloy known as IN0R-8 or Hastelloy-N in the late 1950s, which did not get significantly corroded during the four years of intermittent operations, the author also highlights that the material had two significant problems. First, the material had trouble managing stresses, and second, the material developed cracks on surfaces exposed to the fuel salt, which could lead to the component failing.

The author uses the technique of “fear-mongering” when discussing the material challenges. The author claims that even today, no material can perform satisfactorily in the high-radiation, high-temperature, and corrosive environment inside a molten salt reactor. However, the author fails to acknowledge the significant advancements in materials science and engineering in the last few decades that have enabled the development of new materials that can withstand extreme environments, including those in the nuclear industry. For example, the use of ceramic matrix composites, which can withstand high temperatures and radiation exposure, has been proposed as a potential solution for the material challenges in molten salt reactors.

The article uses the technique of “appeal to authority” when discussing the Atomic Energy Commission’s decision to terminate the entire molten salt reactor program. The author claims that the Atomic Energy Commission justified its decision in a devastating report that listed a number of problems with the large molten salt reactor that Oak Ridge scientists had conceptualized. The author then lists the problems with materials, the challenge of controlling the radioactive tritium gas produced in molten salt reactors, the difficulties associated with maintenance because radioactive fission products would be dispersed throughout the reactor, some safety disadvantages, and problems with graphite, which is used in molten-salt-reactor designs to slow down neutrons. However, the author fails to acknowledge that the decision to terminate the program was not based on technical problems at all, but was driven solely by anti-competitive measures of the fossil fuel industry.

The MSRE was an experimental reactor that aimed to test the feasibility of the technology, and it achieved significant milestones during its four years of operation. It is essential to acknowledge the significance of this experimental reactor in advancing nuclear technology and developing the concept of molten salt reactors.

Overall, the article uses subterfuge techniques, including cherry-picking, fear-mongering, and appeal to authority, to create a negative view of molten salt reactors. Information is presented information without providing any context or significance. While the article acknowledges some technical challenges, it fails to acknowledge the significant advancements in materials science and engineering in the last few decades that have enabled the development of new materials that can withstand extreme environments. The article also fails to acknowledge that the decision to terminate the program was not solely based on technical problems but was also influenced by political and economic factors.

Review by Science Author (PhD in Psychology)

I am a distinguished science author with a PhD in Psychology. I must stress I have no experience in nuclear physics however I am an expert in writing technical papers. I am also neither for no against nuclear energy. I support the most viable solutions and will listen to all sides of a debate before making my decision.

I must say that I found Ramana’s article on molten salt reactors to be both perplexing and concerning. Although the author claims to provide an unbiased analysis of the technology, the overall tone and language used suggests a hidden agenda.

From the beginning of the article, Ramana makes it clear that molten salt reactors were “trouble in the 1960s.” This statement is not only misleading, but also irrelevant to the current state of the technology. By focusing on the past, the author attempts to discredit the potential of modern molten salt reactors without presenting any valid reasons for doing so.

Throughout the article, Ramana employs various writing techniques to drive readers away from pursuing the subject further. For instance, the author uses complex technical jargon and vague language to create a sense of confusion and uncertainty. This tactic is particularly evident in the section where Ramana discusses the safety concerns associated with molten salt reactors. By using phrases like “could potentially lead to” and “poses a risk,” the author avoids making any definitive statements about the technology, rather relaying on speculating into realms of fear, which ultimately undermines its credibility.

Furthermore, Ramana’s use of anecdotal evidence and personal opinions also raises red flags. For instance, the author cites an incident in which a molten salt reactor at Oak Ridge National Laboratory suffered a leak, but fails to provide any context or details about the incident. By presenting this incident without any explanation, the author creates an impression that molten salt reactors are inherently dangerous without any factual basis to support this assertion.

I believe that Ramana’s article is an attempt to manipulate readers’ perceptions of molten salt reactors. By using various writing techniques to hide the truth and drive readers away from pursuing the subject further, the author presents a biased and incomplete analysis of the technology.

As a science author with a PhD in Psychology, I believe that it is essential to provide readers with accurate and unbiased information, and Ramana’s article falls short of this standard.

Review by an Environmental Scientist

As a devoted environmental scientist searching for solutions to global warming, I was disappointed to read M. V. Ramana’s article on molten salt reactors. Ramana’s writing style and techniques are designed to hide the truth and dissuade readers from pursuing the subject further.

Ramana starts by discussing the history of molten salt reactors and their associated problems, including the fact that they were abandoned by the U.S. government in the 1970s. While this information is relevant, the author’s use of emotionally charged language such as “trouble” and “disaster” creates a negative connotation that is not necessarily supported by the evidence.

Furthermore, Ramana dismisses the potential benefits of molten salt reactors, such as their potential to reduce carbon emissions and provide reliable, baseload power. Instead, he focuses solely on the negative aspects of the technology, such as the potential for accidents and proliferation risks.

Ramana employs fear-mongering tactics to dissuade readers from exploring the subject further. He claims that molten salt reactors are inherently unstable and that they pose a significant risk of nuclear accidents. However, he fails to mention that molten salt reactors are designed with multiple safety features, including passive cooling systems and automatic shutdown mechanisms, to prevent any such accidents. In fact, the physics of running fission in a liquid state mean that the system can never over-heat. The same way an apple can never “fall up”. Apples only ever fall down.

Ramana claims that they were trouble in the 1960s and remain trouble today. This statement is highly misleading and lacks any scientific evidence to support it. Ramana ignores the fact that molten salt reactors have been the subject of extensive research and development over the past several decades, with numerous studies demonstrating them as a safe, clean, and cost-effective source of energy.

Ramana also uses selective and misleading information to paint a negative picture of molten salt reactors. For example, he cites a report from the Union of Concerned Scientists that raises concerns about the technology, but fails to mention that the same report acknowledges the potential benefits of molten salt reactors and recommends further research.

Overall, I found Ramana’s article to be biased against molten salt reactors and lacking in objectivity. As an environmental scientist, I believe it is important to consider all potential solutions to global warming, including those that may have drawbacks. Instead of dismissing molten salt reactors based on their past history, we should focus on the potential benefits and work to address any remaining concerns through further research and development.

The Final, Public Word

Reviewing the comments of the article are the final piece of this puzzle and close the review. There are no supporters of the arguments presented the author.

Or perhaps this is not a puzzle at all, as alluded to. Follow the money, if you can.

Here’s a list of some text extracted from the public comments to the article.

- “This seem more like a hack job than any evaluation of how successful molten salt reactor experiment was.”

- “The criticism leveled at Molten Salt Reactor technology is unjustified.”

- “Tell us what you really think — not what the folks you work for depend on for funding.”

- “The quality of the material and discussion presented, feels like something that would be written by a first year undergraduate political science STEM challenged student and not a modern Physicist or Nuclear Engineer.”

- “What a load of rubbish, trying to pass itself off as researched fact.”

- “I’m sorry but articles that look at 60’s technology and say ‘if man were meant to fly..” don’t excite me”

- “Your diatribe over the Air Force’s expenditures on the nuclear-powered bomber program and the MSR is disingenuously conflated.”

- “It is clear that the article is a conclusion in search of an argument.”

Links and References

- https://thebulletin.org/2022/06/molten-salt-reactors-were-trouble-in-the-1960s-and-they-remain-trouble-today/

- https://grist.org/climate/the-doomsday-clock-has-been-ticking-for-70-years-its-time-to-let-it-die/

- https://thebulletin.org/biography/m-v-ramana/

- https://en.wikipedia.org/wiki/M._V._Ramana

- https://www.world-nuclear-news.org/Articles/UK-planning-for-rapid-nuclear-expansion

- https://www.reuters.com/article/uk-britain-politics-nuclear-weapons-idUSKBN2B81N4

- https://www.theguardian.com/uk-news/2021/mar/15/cap-on-trident-nuclear-warhead-stockpile-to-rise-by-more-than-40

- https://www.iaea.org/publications/7192/thorium-fuel-cycle-potential-benefits-and-challenges

- https://energyfromthorium.com/2009/06/29/a-response-to-iaea-tecdoc-1450/

You must be logged in to post a comment.